It’s been more than a year since COVID-19 made its mark by affecting almost every part of our lives. Working remotely while homeschooling our kids, little to no public entertainment, extreme pressure on our healthcare systems, and a surge in demand for personal protective equipment (PPE), are examples of the impact. Along with healthcare institutions, the public has been in need of PPE due to changing regulations. Unfortunately, however, production capacity is not the same for all PPE, mainly because of limited access to raw materials and fewer manufacturing options.

Unlike facemasks, for which new production capacity can be built relatively quickly and inexpensively, there is almost nothing that can be done, in the short term, to increase the supply of exam gloves. About nine months are required to build a new nitrile glove production line. Moreover, you’ll need at least another year for production of nitrile butadiene rubber, the primary raw material, to be significantly increased. The above-mentioned demand puts a lot of strain on the supply chain of nitrile exam gloves worldwide. Suppliers also struggle as their production capacity is at its limit.

Current market conditions

The market for nitrile exam gloves is currently suffering from several disruptive factors. MedTech Europe reports the following as the most impactful:¹

- Increased demand – Global consumption of exam gloves has surged since early 2020 due to increased awareness of the importance of PPE, panic-buying and new customers, and customer segments in development.

- Constrained supply – Setting up new production lines is both time-consuming and expensive. To make matters worse, COVID-19 outbreaks have compromised existing lines while raw materials and other manufacturing components are constrained.

- Fraudulent offers – There have been incidents of questionable suppliers entering the market with fraudulent and unregulated offers and/or exploiting the current state of the market by asking for unusual and disproportionately high prices. As a result, more consumers and their patients are at risk.

- Rising costs – The cost of nitrile raw material is increasing due to high demand. In addition, production- and workforce-related costs are on the rise due to production limitation and opportunists who increase prices on the market.

Substitution as a solution

In healthcare settings where there is the greatest need for nitrile gloves, the supply chain issues I’ve mentioned are extremely impactful. Therefore, we have to rethink the way we use PPE, and free up nitrile glove capacity. This way, the departments where healthcare professionals need protection most have access. These include laboratories, pharmacies and central sterile (CS).

As a gloves manufacturer and supplier, Medline proposes nitrile substitution as an effective conservation strategy. We encourage replacing nitrile gloves with vinyl gloves in departments where there is limited exposure to harmful chemicals, or bodily fluids. Our vinyl gloves, for example, differ from nitrile gloves in material thickness and physical properties, but have similar safety requirements, such as Medical Devices Directive (MDD) and PPE class 3 certification.

The benefits of applying this substitution include:

- Vinyl alternatives may be more readily available in times of crisis because they tend to not have the same raw material constraints as nitrile options

- Vinyl gloves provide a protective barrier during routine tasks that do not require the use of or exposure to hazardous chemicals and/or drugs

- Vinyl as a replacement means reduced supply constraints and pressure on nitrile gloves supplies. This, in part, ensures higher availability of nitrile gloves to departments where these are a necessity.

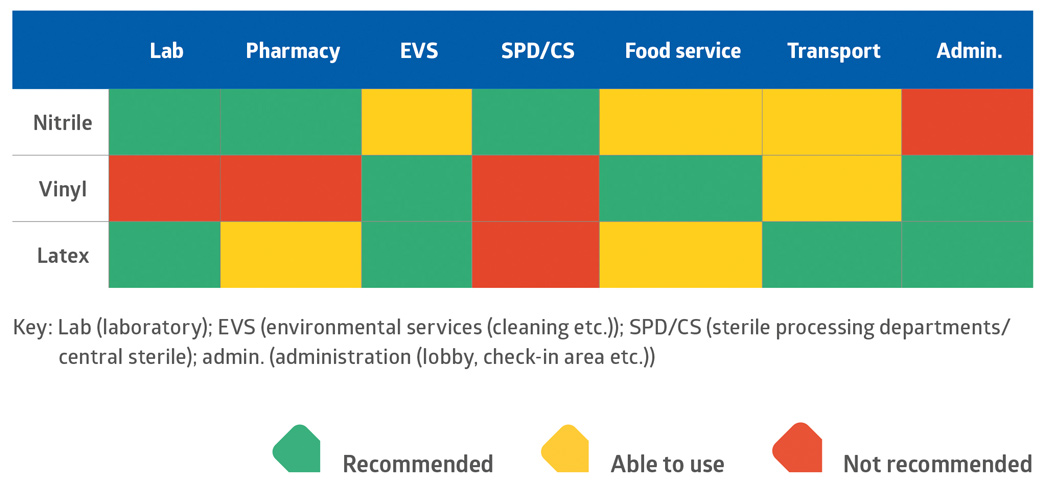

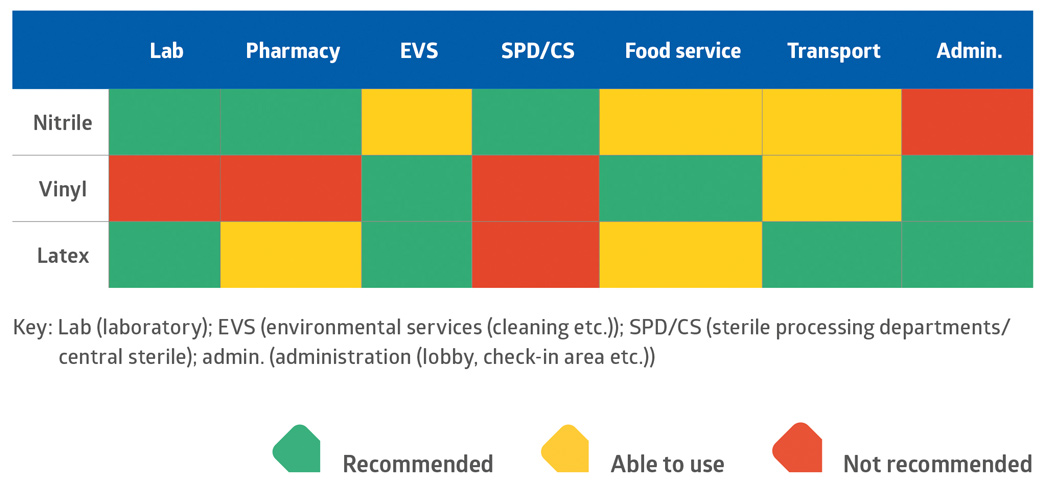

Gloves by department

Through glove substitution, customers can optimise their glove use. Not only is it beneficial when managing a limited supply, but it is also a cost-saving strategy when implemented in the long term. For more information on exam gloves, visit our webpage!

Jeanne Verheyden

Exam Gloves Division, Medline Europe

Jeanne is a recent graduate from Vrije Universiteit Amsterdam, and received her Master’s degree right before joining Medline Europe as a Junior Product Manager. Her educational background is in international business and business administration, and during her studies she completed internships in Germany and the United Kingdom.